It's that time of the year, again, when families across the country are messing with long strings of electrical wire, crazy light bulbs, and LEDs plus all sorts of weird objects made of ceramic, glass, metal or plastic. I was inspired to offset some of my Grinchiness by using our put-up-the-decorations day as another opportunity to use one of my new favorite materials.

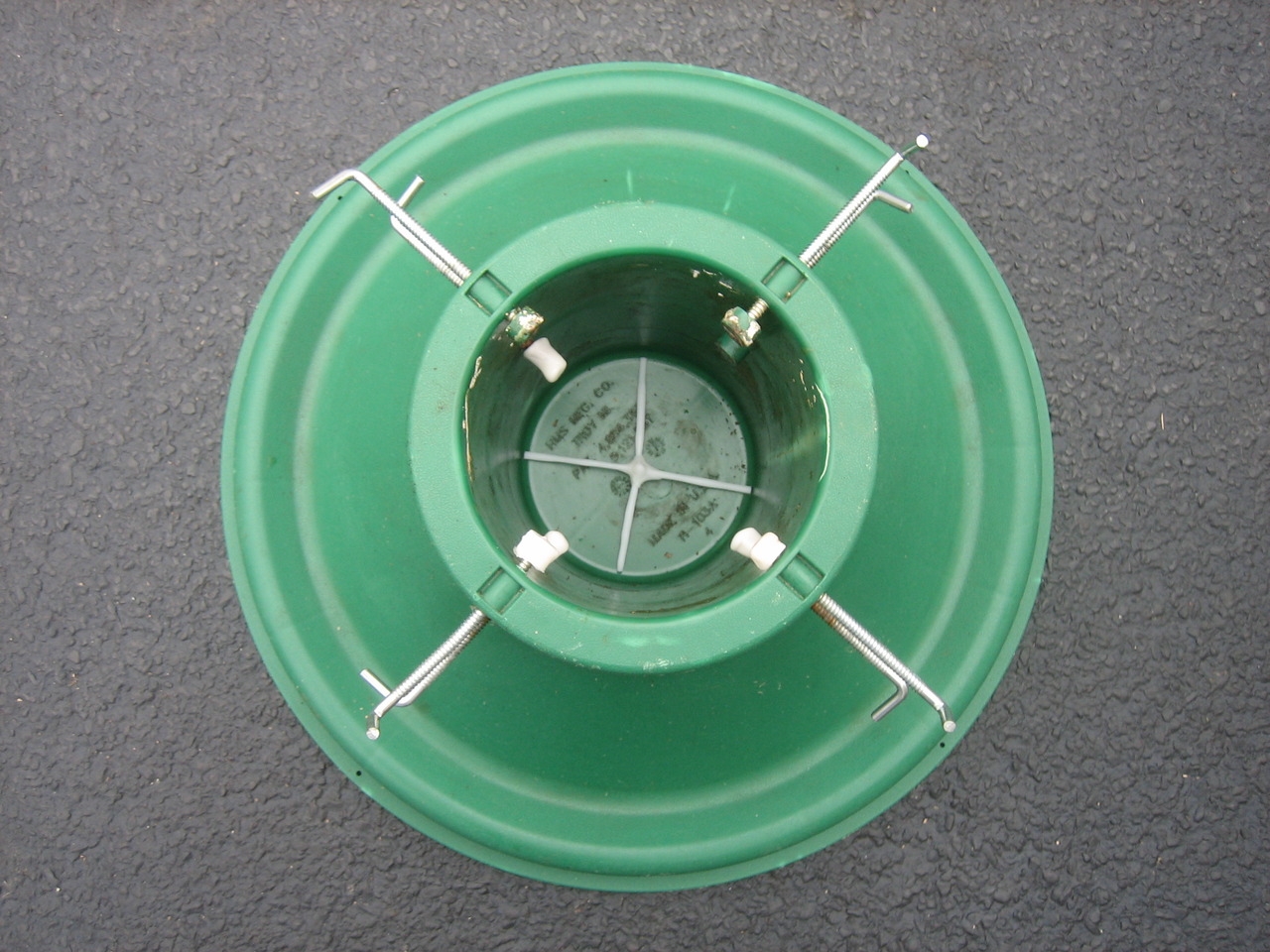

Our Christmas tree stand has this nifty tiered collection of what are, essentially, big set screws, designed to hold the trunk of the tree upright in the center of the tree stand. Problem is, over time we've lost the little plastic caps from the trunk end of several of the set screws. This means the set screws tear up the bark of the tree trunk more quickly, and dig more easily into the trunk of the tree.

That can't be good.

Also, another of our tree stands, smaller, with only one tier of set screws, has a nice little conical stand-off built into the bottom of the stand, to help keep the bottom of the tree off the bottom of the stand. That way water can get into the bottom and up through the tree. The larger stand that we like to use, with two tiers of set screws, has no such stand-off.

So, I made little caps out of PCL (polycaprolactone, aka Shapelock aka Friendly Plastic, about which perhaps more some other time) to replace the missing ones.

I made a mold out of some polymer clay using the OEM green cap and made one PCL cap with the mold. Using polymer clay this way is something I've been meaning to try. Sad to say, that approach still needs a little work--I had a lot of trouble with the PCL locking into small imperfections in the mold. The rest of the replacement caps I made by just pressing warm PCL around the ends of the set screws, free form, and then letting them cool and harden in place.

I also made a little PCL stand-off to put in the bottom of the tree, with a little "spider" consisting of two crossed PCL rods to help keep it near the center of the bottom of the well of the stand.

Here they are, all together:

The caps seem to have worked pretty well. The spider kept slipping out of place as I was trying to get the stand fit onto the tree. Next year maybe I'll try putting something soft and sticky on the ends to help with more of a press-fit, either some sort of generic silicone caulk or some Sugru or something.